Abstract

Centrifugal casting techniques are widely applied throughout the industrial business. To fully understand both mechanical and physical characteristics of the very techniques may be beneficial for pursuing the optimal products in the best quality at a reasonable cost.

The following contents covered in this article, will give you a refined introduction to centrifugal casting, from types of centrifugal casting to the application of centrifugal casting, hoping to provide you a clear image of the techniques.

Contents

What is Centrifugal Casting?

Centrifugal casting, also known as Liquid Forgings, refers to casting techniques that are taking advantage of centrifugal forces of rotation. While revolving, the substances within the molten metal scatter to different layers according to the density by the high compressive pressure. The molten metal will eventually solidify on the outer regions of a circular mold cavity and create parts for certain use.

Centrifugal casting technique was invented by Alfred Krupp in 1852. Date back to the time, centrifugal casting techniques were mainly applied on frames of tires of trains. Nowadays, in addition to transportation machines, centrifugal casting is broadly used in various fields like industrial, military and metallurgy applications.

Contemporarily, centrifugal casting techniques are majorly conducted either vertically or horizontally. With the different direction of the axis, requiring the different machines to manufacture. Vertical centrifugal casting goes to vertical centrifugal casting machines, while horizontal centrifugal casting goes to horizontal centrifugal casting machines. There are also tilt centrifugal casting (Durville Pouring Process), but rarely applied. Therefore, the following paragraphs are going to put the emphasis on documenting more info about the two dominant types of machines, vertical centrifugal casting and horizontal centrifugal casting.

Vertical Centrifugal Casting Machines

Vertical Centrifugal Casting Machine

Vertical centrifugal casting machines operate on the vertical axis and rotate around the y-axis where the axis is in a vertical or almost vertical position or direction. Graphite, ceramic, or other similar materials are frequently produced via the mold due to the orientational characteristics.

Many could be misunderstanding that vertical centrifugal casting is confined to symmetrical production. Yet, it is not correct. centrifugal casting is capable of producing asymmetrical parts. Despite the seemingly flexible shape options, the casting width is bound to be twice its height, limiting the size of the product as a matter of course.

Horizontal Centrifugal Casting Machines

Horizontal Centrifugal Casting Machine

Horizontal centrifugal casting machines enable manufacturers to produce pipes, tubes, and other similar products effectively and economically. The casting process rotates horizontally around the x-axis, where the horizontal angle is smaller than 4 degrees.

Under most circumstances, vertical centrifugal casting machines are larger and heavier than horizontal centrifugal casting machines. In effect, the former is mainly used to manufacture the larger components(Φ700~Φ800mm), while the latter is for castings that are in a smaller scale(Φ80~Φ90mm). Corresponding to different needs, producers may need to produce their parts with moderate applications of two different types of machines that may bring the utmost benefits.

After knowing the types of machines that are capable of executing centrifugal casting, Let’s take a further look at types of centrifugal casting. Centrifugal casting can be divided into 3 types, True centrifugal casting, semi-centrifugal casting, and centrifuge casting.

True Centrifugal Casting Technique

True centrifugal casting can be horizontal or vertical. The horizontal axis revolved made items possess high-intensity applications, cylinder liners, for example.

Generally speaking, the physical properties like the density and strength of the product depend on the revolving speed of the centrifugal casting machine, together with the moderate positioning of the mold and other factors, brings out the best overall results of centrifugal casting.

The mechanical strength of the versatile technique delivers the best-performing products with lowest impurities and highest efficiency. However, true centrifugal casting is limited to compose cylindrical or circular items and in a higher time demands, which can delay the delivery.

Semi-Centrifugal Casting Technique

Semi-centrifugal casting is capable of delivering a solid product unlike a tubular cast. In comparison to true centrifugal casting, semi-centrifugal casting offers you items in differing densities. The exterior area is with a higher density. The closer the casted object is near the axis, the lower the density they possess.

In spite of the highlights we mentioned, the overall quality of semi-centrifugal casting technique depends on all of the factors, including the rotational speed, diameters used, pouring temperature etc. It turns out that semi-centrifugal casting is under the greater risk of producing defective items than true centrifugal casting technique.

Centrifuge Casting Technique (Centrifuging)

Sophisticated items with considerable surface features, such as jewelry, small bushes, are preferred to adopt centrifuge casting technique (centrifuging). Due to the fact that, during centrifuge casting (centrifuging), the designed shape of the produced components formed by the centrifugal forces pushes the molten metal into the corresponding mold cavity in a certain shape and diameter from the axis.

Centrifuge casting (centrifuging) is able to produce parts with complicated features while free of any post-processing, since the mold cavity is far from the center whereas the rotation forces leave impurities inwards the axis, cutting down casting-related defects during the manufacturing process. Yet, there are still disadvantages of centrifuge casting (centrifuging). For example, centrifuge casting (centrifuging) is not open to all means of alloys, which means the material usages are limited. Apart from the limit of materials, the sprue and runner of the technique is likely to affect the overall costs out of the time-demanding of the process.

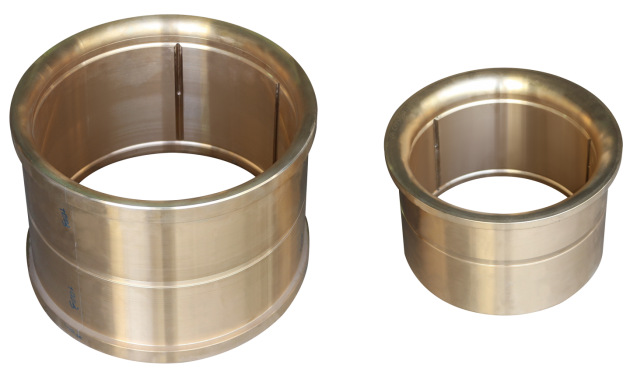

Copper Alloy Bushing -Tin Bronze

What are the Features of Centrifugal Casting?

We have elaborated on the types and comparison of different centrifugal casting techniques in detail, which may spur the curiosity of you to the general features of centrifugal casting. Next, we are going to take a further step into features of centrifugal casting.

In contrast to other manufacturing techniques, forgings and fabrications for instance, centrifugal casting is economically effective and efficient for creating delicate near-net shape components due to the features of centrifugal casting. Here are the features of centrifugal casting, including:

-

Centrifugal-casted metal purity is competent to bear greater overload with the minimum scraps while manufacturing.

-

The physical properties of centrifugal-casted metal like tensile, creep and fatigue strength, can be boosted up to 30% on the contrary to static and investment casting methods.

-

Blowholes, porosity and inclusions of the metal are able to be removed easily, before finish machining.

-

Centrifugal-casted parts can be in hollow interiors without cores.

-

Defective parts and material waste is significantly decreased, saving valuable machining time, bringing you low equipment and labor cost.

-

Centrifugal casting is capable of building giant parts accurately.

-

Since the centrifugal forces fill the cavity, small parts with thin-walls can be produced.

-

The amount of forces from centrifuges imparted evenly on the molten metal smooth the surfaces of the composed parts.

-

The composed parts are with larger density out of the fact that the cast parts are further from the rotational axis.

What are the Key Characteristics to the High Speed Centrifugal Casting Process?

To manufacture the ideal parts, high speed centrifugal casting techniques rotate persistently at 300 to 3000 rpm. The higher the speed, the more pressure on the molten metal. The key characteristics to high speed centrifugal casting techniques as follows:

-

Boosting Physical Properties

High-velocity centrifugal casting process produces parts that undergo pressures many times that of gravity, which contributes to a denser, close-grained structure with greatly improved physical properties.

-

Displacing Oxides and Impurities

While spinning, due to the difference in density, the lighter oxides and impurities will be displaced and forced to float toward the central axis that can be removed later during the boring operation.

-

Flawless and Smooth Surface

High-velocity centrifugal castings free parts from shrinkage cavities, gas pockets, and blowholes since they freeze from the outside surface inward instead of the regular gravity or static casting processes chilling from both the inside and outside surfaces.

Which Materials are Suitable to Use Centrifugal Casting?

Architectural or industrial materials are often taking advantage of centrifugal casting techniques. Varying from the physical and the chemical properties, different materials suit various process techniques, while materials are suitable for centrifugal casting including:

Metals

Copper Alloys

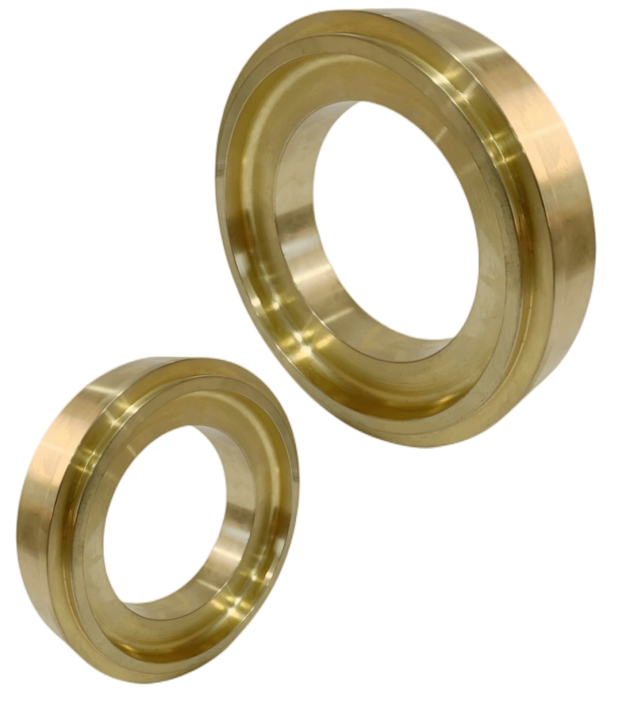

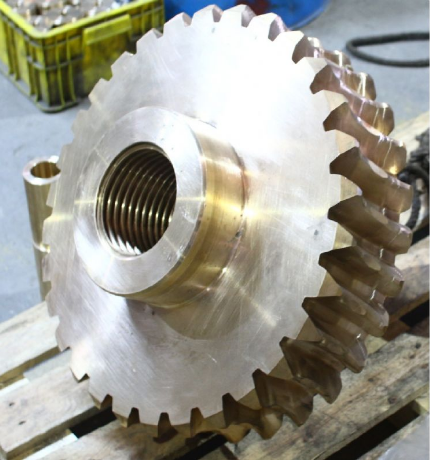

Such as phosphor bronze, gunmetal copper, aluminum bronzes (copper worm gear and worm), high tension brass, silicon bronzes, nickel silvers, cupronickel and so on.

Phosphor Bronze-PBC-C90700

Gunmetal Copper-BC6-C83600

Aluminum Bronze 3-ALBC3-C95800

High Tension Brass - HBSC3-CuZn25Al5Mn4Fe3-C

Stainless steel

Such as chromium-manganese-nickel alloys (200 series stainless steel) and chromium-nickel alloys (300 series stainless steel) etc.

Special Steel

Iron that contains various elements to achieve various properties for specific use can be difficult to process, centrifugal casting is able to manufacture parts in special steel.

Glasses

To produce a delicate and smooth surface of glasses for specific use, features of centrifugal casting make it a preferred choice.

Concrete

Centrifugal casting can easily compose cylindrical shapes with hollow interiors, which is beneficial for architectural purposes.

Which Fields Suit the Applications of Centrifugal Casting Techniques?

Transportation Machines

Transportation machines such as ships, trains, aircrafts and vehicles, usually function under harsh working conditions, living up with corrosion, erosion and cavitation. Metals produced by centrifugal casting are usually with minimum scraps yet have the ability to withstand greater overload, which are suitable to be employed on such machines.

Industrial Machines

Similar to the statement above, industrial machines are often demanding parts that are able to work under strict environments, making centrifugal casting products meet the needs. What is more, centrifugal casting can manufacture huge parts with high accuracy, cutting down the trifling waste on materials and making sure the machines work precisely. Common applications like press machines, rotary table, gear box, lift gear unit and pharma machine.

Centrifugal Casting Product OD1200mm

Centrifugal Casting Product OD1500mm

Military Machines

To adapt to all kinds of extreme conditions, the parts of military machines should be able to withstand tough circumstances. Centrifugal casting offers components with denser physical properties and free from impurities.

Mining and Metallurgy

Centrifugal casting is efficient and economical when it comes to extracting the substances from minerals, because the centrifugal forces can easily deconstruct the structure of the mineral, reassembling the order of the material.

Corresponding to different and specific feature needs of components in various professional fields, via centrifugal casting, manufacturers can compose parts with high mechanical properties that are suitable for aggressive working conditions.

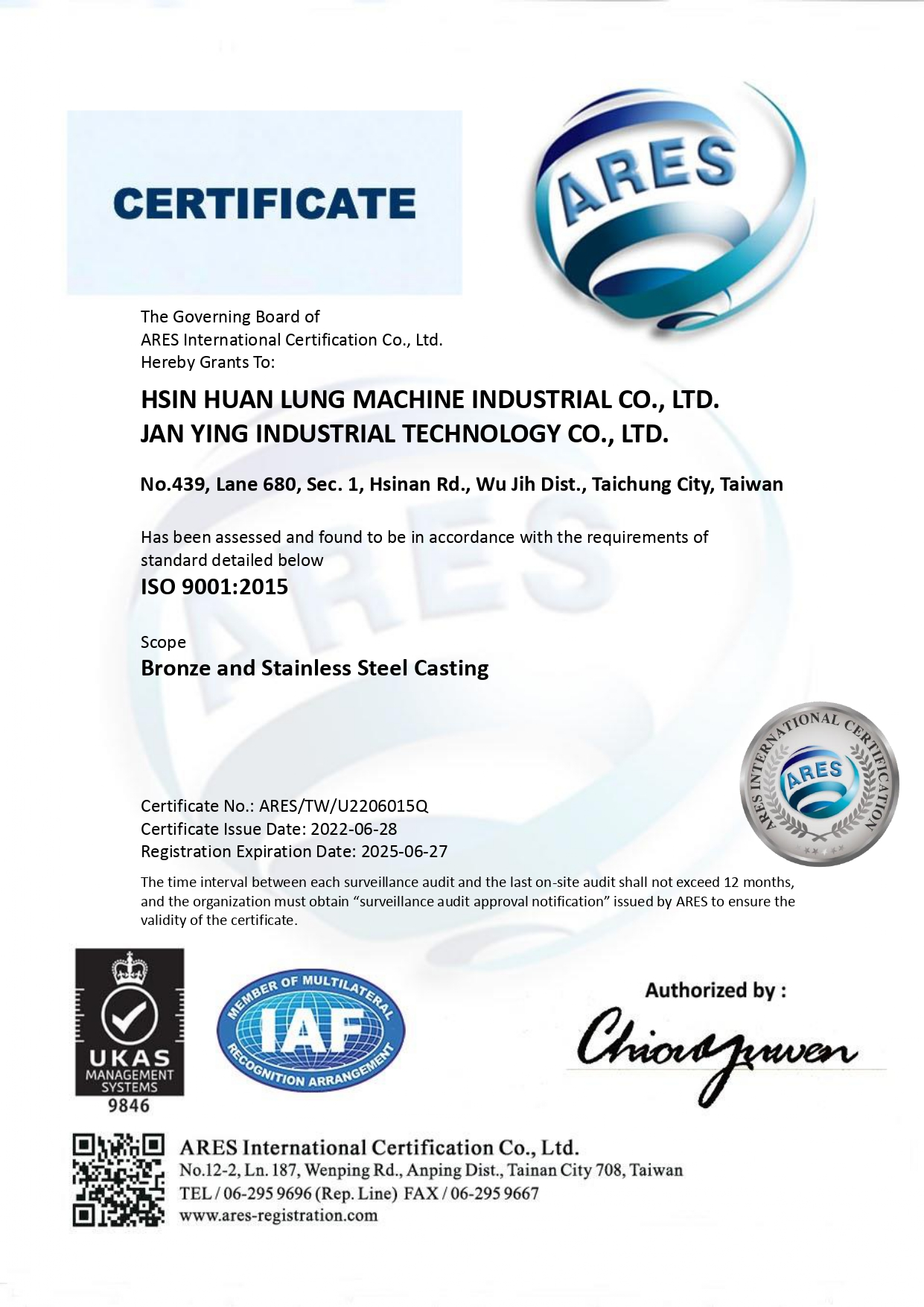

The Advantages of HSIN HUAN LUNG MACHINERY INDUSTRIAL COMPANY (HHL)

HSIN HUAN LUNG MACHINERY INDUSTRIAL COMPANY (HHL) is the largest specialized bronze and stainless casting and manufacturing factory in Taiwan. Our main products are casting bronze alloy for the machine tool industry and stainless steel.

Established in 1977, HHL specialized in producing brass casting and being in honor to fulfill customers’ needs with the best quality, competitive price, and fast delivery. With 15-year professional centrifugal casting techniques, HHL is dedicated to offer the best centrifugal casting products.

-

Advanced, Efficient and Professional Equipment:

We constantly introduced high quality equipment, advanced technology and precision inspection instruments into our company. We provide outstanding products with the most advanced High Frequency Induction Furnace, Vertical Centrifugal Machine, Horizontal Centrifugal Machine, Sand Preparation Equipment and Furan Equipment.

High Frequency Induction Furnace

Vertical Centrifugal Machine

Horizontal Centrifugal Machine

-

4 Forms of Casting Techniques:

4 major casting techniques, Sand casting, Centrifugal Casting, Furfuryl Alcohol Casting and Permanent Mold Casting satisfying your needs.

-

Various Materials for Centrifugal Casting Customization:

HHL offers centrifugal casting to various kinds of materials, including copper alloys, special steel and stainless steel. Contact us to get more details about feasible materials.

-

Customize in Small Quantities:

From mass production to small-batch production, we provide products with dimensions, material customizable. Seeking tailored components? HHL is devoted to fulfilling all your needs.

-

Attains to Sincerity, Fulfills Your Needs:

HHL is qualified to ISO 9001:2015 Quality Management System. Over the last thirty years, HHL assures our clients of high and stable quality. To satisfy our clients, we set up a Machining Department and cultivate our own professional machining team, so that we can provide them with finished machined components.

Contact HHL To Get a Satisfying Order

COPPER: 886-4-23350012

STAINLESS STEEL: 886-4-23358196

FAX: 886-4-23350006

MAIL: hhl.sales1@gmail.com

ADD: No. 439, Lane 680, Section 1, Xinan Road, Wuri District, Taichung City

Related Info: Copper Bronze Centrifugal Casting|Copper Bronze Manufacturer