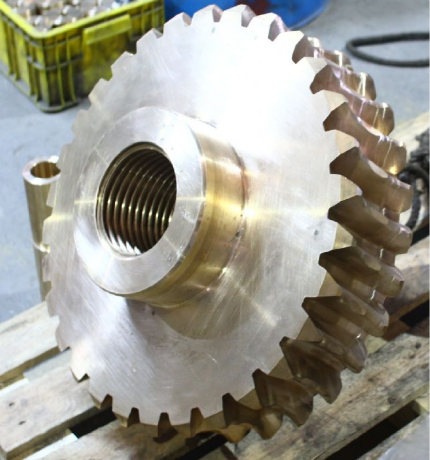

Copper Alloy Bushing -Tin Bronze

Description:

*Dimension:

OD:76MM~2500MM (3"~98")

Length: up to2300MM

*Material Proteries:

- High quality mechanical properties

- Good slip properties

- Slight self-lubrication capacity

Products Applications :

-Bushing

-Bearing

-Bronze nuts

-Springs

-Worm and worm gear

-Machinal parts

-Vassal parts

Similar Material:

JIS CAC502、JIS CAC502C、JIS CAC503

ASTM C90700 、 ASTM C91000

CC480K、CC483K

CuSn10-C、CuSn11-C

CuSn12Ni2

CC483K、G-CuSn12Ni

DIN 1705、CB484K

Our Advantage:

Dimensions customizable.

Material customizable

CuSn12Ni2, a widely used alloy in various industries, boasts a versatile composition and exceptional properties that cater to a spectrum of applications. The provided table outlines a typical chemical composition of CuSn12Ni2, albeit variations may exist depending on manufacturers and specific application demands.

Classified under different material designations in standards like DIN EN 1982 and DIN 1705, CuSn12Ni2 is available in various casting methods including sand casting (GS), centrifugal casting (GZ), and continuous casting (GC).

Chemical Composition of CuSn12Ni2

The table demonstrates a common composition of CuSn12Ni2, while the actual composition may vary slightly depending on the manufacturer and the specific requirements of the application.| element | percentage |

| Copper (Cu) | 85.0% - 88.0% |

| Tin (Sn) | 10.0% - 12.0% |

| Nickel (Ni) | 1.0% - 3.0% |

| Lead (Pb) | 0.10% maximum |

| Zinc (Zn) | 0.50% maximum |

| Iron (Fe) | 0.20% maximum |

| Phosphorus (P) | 0.03% maximum |

| Sulfur (S) | 0.08% maximum |

| Other elements | 0.50% maximum |

Material designation

GS = G = Sand casting; GZ = Centrifugal casting; GC = Continuous casting

| DIN EN 1982 | DIN 1705 | |||

| Abbreviated designation | Number | Casting method | Abbreviated designation | Number |

| CuSn12Ni2-C-GS | CC484K-GS | GS or G | G-CuSn12Ni | 2.1060.01 |

| CuSn12Ni2-C-GZ | CC484K-GZ | GZ | GZ-CuSn12Ni | 2.1060.03 |

| CuSn12Ni2-C-GC | CC484K-GC | GC | GC-CuSn12Ni | 2.1060.04 |

CuSn12Ni2's Distinctive Features

CuSn12Ni2 offers several features that make it suitable for various applications including:

-

High strength and hardness

suitable for heavy-duty applications, such as marine equipment, bushings and gears. -

Reliable Wear Resistance

ensures that it can withstand frequent use without wearing down or breaking. This property enables CuSn12Ni2 for use in bearings and other high-stress applications. -

Exceptional Corrosion Resistance

It is feasible to employ CuSn12Ni2 in marine equipment and other applications that are exposed to harsh conditions since it has excellent corrosion resistance, making it resistant to various chemicals and environmental factors, such as saltwater. -

Superior Machinability

This feature allows manufacturers to create complex shapes and designs using the alloy that CuSn12Ni2 is highly machinable, making it easy to work with during manufacturing. -

Superb Weldability

making it easy to join with other metals during manufacturing. -

Outstanding Electrical Conductivity

high conductivity, which makes it a popular choice for electrical contacts and connectors. -

Endurance Against Fatigue

The resistance to fatigue and a low coefficient of friction of CuSn12Ni2 enables it to withstand repeated stress without breaking or wearing down

Related products